For the grow room design that has too much height, how to set up grow lights with tall ceilings becomes a major challenge. Or, sometimes the existing grow room or greenhouse support frame makes the indoor grow lights difficult to place. Ceiling can also be slanted, canted or have structural obstacles. Or, grow room design structures can be awkwardly shaped. And, that can be found in make-shift greenhouses, Quonset huts, hoop houses and the warehouse grow setup. Each of these grow room setups have specific design needs. And, these unique indoor grow setups make us wonder how to best plan grow light placement. So, how to set up grow lights with tall ceilings is a major grow equipment question for the indoor grow room setup.

For the grow room design that has too much height, how to set up grow lights with tall ceilings becomes a major challenge. Or, sometimes the existing grow room or greenhouse support frame makes the indoor grow lights difficult to place. Ceiling can also be slanted, canted or have structural obstacles. Or, grow room design structures can be awkwardly shaped. And, that can be found in make-shift greenhouses, Quonset huts, hoop houses and the warehouse grow setup. Each of these grow room setups have specific design needs. And, these unique indoor grow setups make us wonder how to best plan grow light placement. So, how to set up grow lights with tall ceilings is a major grow equipment question for the indoor grow room setup.

The perfect scalable solution

LightRail light movers at an aquaponic farm.

The setup above is a clean, logical design by The Aquaponic Source, and the setup below is from commercial grow room design plans, as another example. You’ll see they are perfect for tall ceiling settings. And, they are scalable for any sized indoor grow setup, and they provide multiple indoor grow room setup solutions. Plus, because of the structural support bars, these indoor grow systems work in the most challenging indoor grow setups. Whether in a greenhouse or grow room, and whether for indoor farming or cannabis cultivation, there are grow room ceiling solutions.

Then, as a component in each, a LightRail light mover is in place along with the upper bar support. The grow light mover enables the grow light to be positioned close to the canopy. And, that results in maximum Ppfd. That’s to more plant area in the form of intensely strong, but intermittent, indoor plant light. And, that’s how we optimize our grow light systems.

Grow lights positioned too high are wasted, geometrically

This is the secret to getting faster growth and much higher yields. Whether we are growing / farming with high ceilings or with very high ceilings such as an airplane hanger or large warehouse, we have this dilemma. We want a close grow light interaction so that our plants get everything they can from our grow lights. So, the Ppfd and the spectrum numbers can either be fully realized, or they can be wasted. Grow lights positioned too high are wasted, geometrically. This grow light system phenomenon is an example of Inverse Square Law, where grow light intensity diminished fast with distance. So, at 5 feet above, the indoor plant light is exactly one half for intensity. At seven feet, it is reduced by 75 percent, meaning we are getting about 25% of what our grow lights have to offer. At nine feet, we are hovering around 10% for grow light system power. It’s shocking how quickly it all goes away with any kind of grow light height.

This is the secret to getting faster growth and much higher yields. Whether we are growing / farming with high ceilings or with very high ceilings such as an airplane hanger or large warehouse, we have this dilemma. We want a close grow light interaction so that our plants get everything they can from our grow lights. So, the Ppfd and the spectrum numbers can either be fully realized, or they can be wasted. Grow lights positioned too high are wasted, geometrically. This grow light system phenomenon is an example of Inverse Square Law, where grow light intensity diminished fast with distance. So, at 5 feet above, the indoor plant light is exactly one half for intensity. At seven feet, it is reduced by 75 percent, meaning we are getting about 25% of what our grow lights have to offer. At nine feet, we are hovering around 10% for grow light system power. It’s shocking how quickly it all goes away with any kind of grow light height.

How to set up grow lights also factors into yield numbers

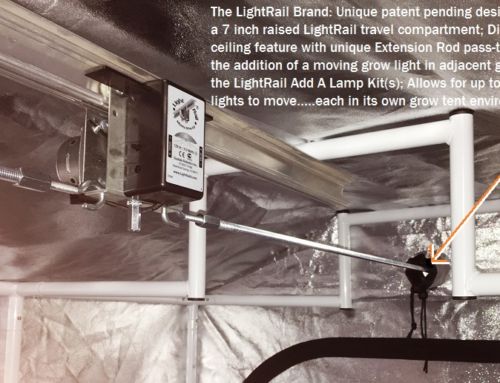

That is a huge waste for what our grow lights could be delivering. But, we can get around this problem of how to set up grow lights with tall ceilings by first, having supports. There are brilliant, ready-made support systems, or you can make your own. Then, to get the grow light system to be even more effective, moving each grow light on a LightRail light mover is seriously effective for yield numbers. For The Aquaponic Source’s setup, upper photo, they use the LightRail Strut Channel Compatible Rail. And then, by simply removing the Strut Channel blue hanger piece and replacing it with a longer bolt, they attach up into their support frame. Super smart. Or, if your support frame is strut channel, or Unistrut, that Rail is the one to use for a perfect fit.

On the fly greenhouse or a grow room Quonset hut

Commercial grow-room design plans that are difficult to envision and include the problem of how to set up grow lights with tall ceilings can be solved. Support structures make the tall and cavernous indoor grow room setup manageable. And, that is the same whether our grow room setup is an on the fly greenhouse or a grow-room Quonset hut. Or, it’s the same for the largest grow warehouse setup with commercial grow lights. Even vertical farming benefits from moving quality grow light bars. And that’s with fewer LED light bars needed. In other words, in all grow room settings the best grow lights move.

So, the best grow room design, and that’s for all of these spaces, involves this.

Closer, and then finesse

We want to create a sub-ceiling support structure. And, from that point, we’ll have the best grow room setup results. We want our grow light system close and maximized. So, the second part of our grow room design involves moving our grow lights on grow light movers. In other words, we get close with grow light placement. And, then we finesse with grow light movement.